CHOPPER PRODUCT LINE

Discover SWEED’s versatile, cutting-edge chopping solutions.

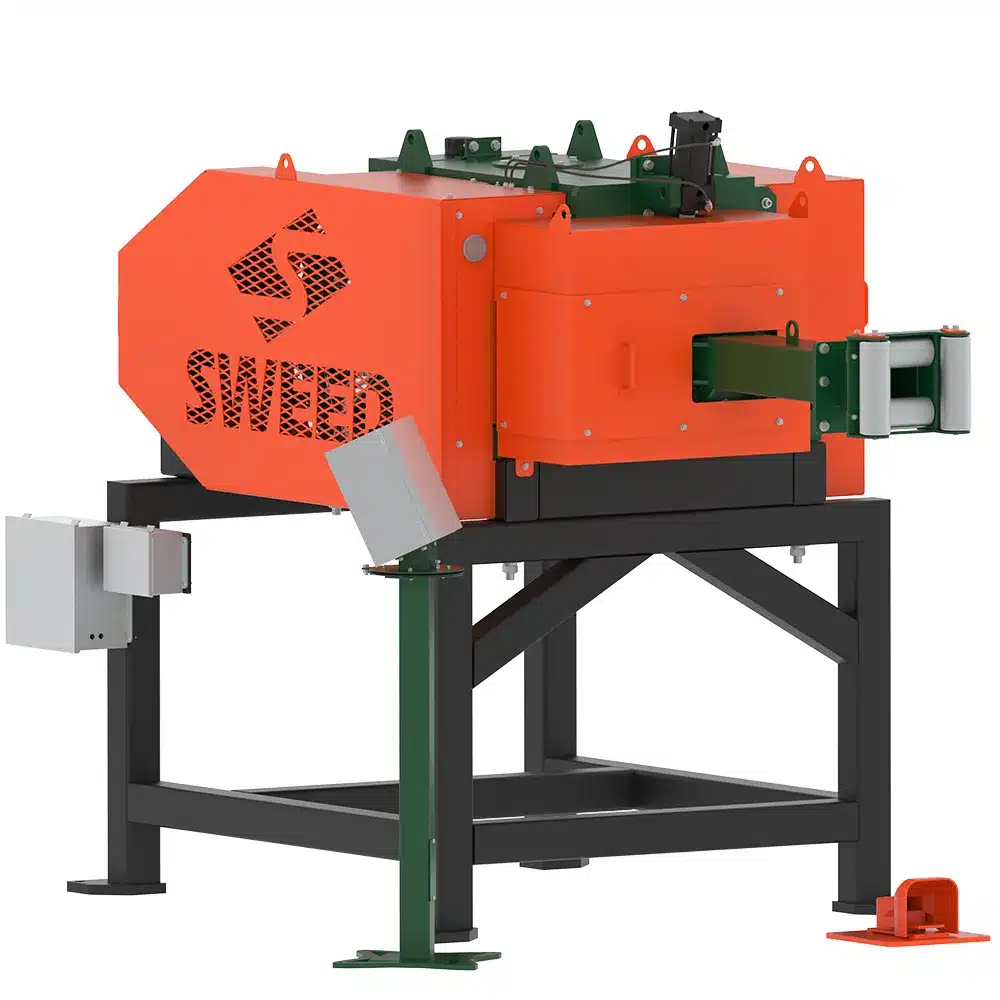

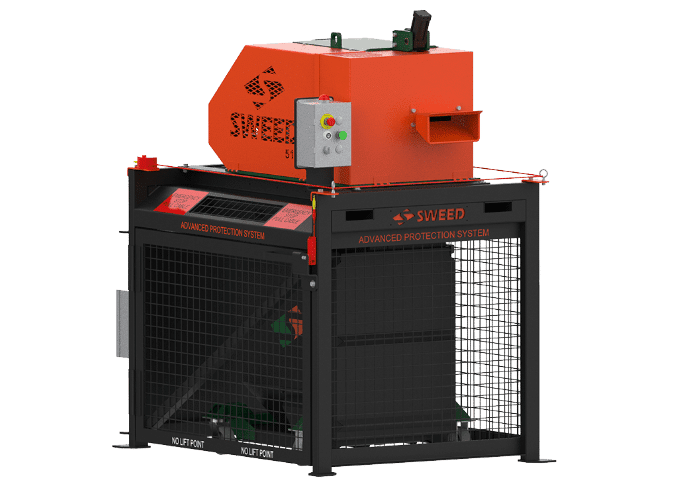

SWEED’s chopper product line efficiently processes a wide variety of linear scrap materials, ranging from PET plastic strapping and steel banding to tube scarf and slitter line scrap, and everything in between. Whether you prefer manual feeding or require a seamless integration within a production line, SWEED’s equipment provides flexible solutions to make scrap processing more efficient.

SWEED’s scrap choppers and smart shears offer remarkable scrap reduction and compaction ratios while operating continuously with minimal maintenance. Experience increased efficiency, enhanced employee safety, and reduced dumpster fees, all while maximizing scrap value across diverse industries. Elevate your manufacturing processes and invest strategically with SWEED to unlock unparalleled efficiency, safety, and cost savings.

SWEED’s innovative cut-to-length choppers are an alternative way to automate the strap cutting process, increase strap cutting efficiency and worker safety.

FILTER

Clear FiltersCategory

Machine type

Features

Material Type

Industry

Electrical Options

Operation

Category

Machine type

Features

Material Type

Industry

Electrical Options

Operation

Chopper solutions for every industry.

SWEED scrap choppers can be custom engineered to meet a company’s production and safety requirements. SWEED choppers can be manually fed, despool scrap material from a reel, or installed into a production line. Cleanup Choppers quickly process plastic and light metals such as polyethylene terephthalate (PET) plastic strapping, and light gauge metal (steel) banding; High Volume Choppers are perfect for larger amounts of steel banding, baling wire, and light cables; Industrial Choppers handle heavy-duty scrap such as telecommunication cable (ACSR, ACSS, MCM, etc.), steel, aluminum or copper rods or tubing; and Specialty and Inline Choppers offer distinctive features to handle unique scrap applications and are typically the choice choppers to be integrated into an existing production line such as those for slitter trim, punch press, stamping, or lines producing tube scarf.

SWEED chopper equipment is also designed with safety in mind. All equipment comes equipped with safety guards and mushroom stop buttons to ensure the safety of operators and employees. Plus, our easily replaceable scrap chopper blades simplify maintenance, reducing downtime.

The right chopper for your company will vary depending on the scrap material and preferred installation.

We’re here to help you make the right choice for you!