Category:

Scrap Choppers

Machine type:

Scrap Chopper

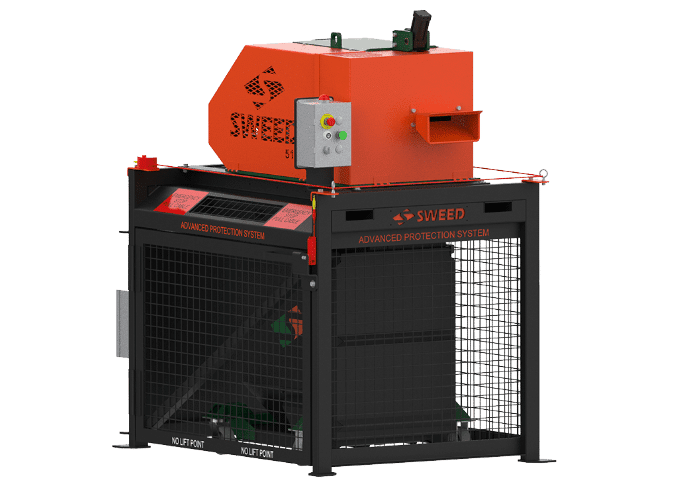

Model 450 DDX

Dual Driven Feedworks Increases Feeding Efficiency.

The Model 450 DDX boasts power alongside a dual-driven feedworks. Driving both feed rolls on the chopper allows the unit to process scrap quickly and efficiently.

The Model 450 DDX is SWEED’s chopper of choice for companies processing large volumes of scrap plastic or PET strapping. This chopper is extremely versatile and can be customized for inline automated production applications requiring tension control and custom scrap lengths. The Model 450 DDX is designed to fit on several SWEED stands that can accommodate a variety of scrap collection containers. Custom stands and additional safety upgrades are also available.

Additional Protection Upgrades

Foot Pedal Operated Feedrolls

Air-activated footswitch that must be depressed to engage the feedworks to pull material into the chopper. If the footswitch is held down for more than 90 seconds, the feedworks will automatically open, preventing continuous operation without active user interaction.

Exhaust Spillway Chute

The exhaust spillway chute underneath the chopper prevents operators from reaching into the material exit chamber. By blocking access to the exit chamber, the chute mitigates potential hazards, ensuring a safer working environment for operators.

Material Reference

The recommended model of scrap chopper is determined by scrap size, scrap volume, and requested custom features. Please consult a SWEED representative to determine the appropriate scrap chopper for your application. The following are materials commonly processed through the 450 DDX:

Up to 1” x .031” steel banding with clip

Up to 1” band saw blades

Most sizes of plastic/PET strap

Construction Features

SWEED scrap choppers are well-known for their robust construction and ability to endure demanding environments. SWEED scrap choppers offer a reliable and efficient solution for processing linear scrap materials while prioritizing durability, safety, and user-friendly operation.