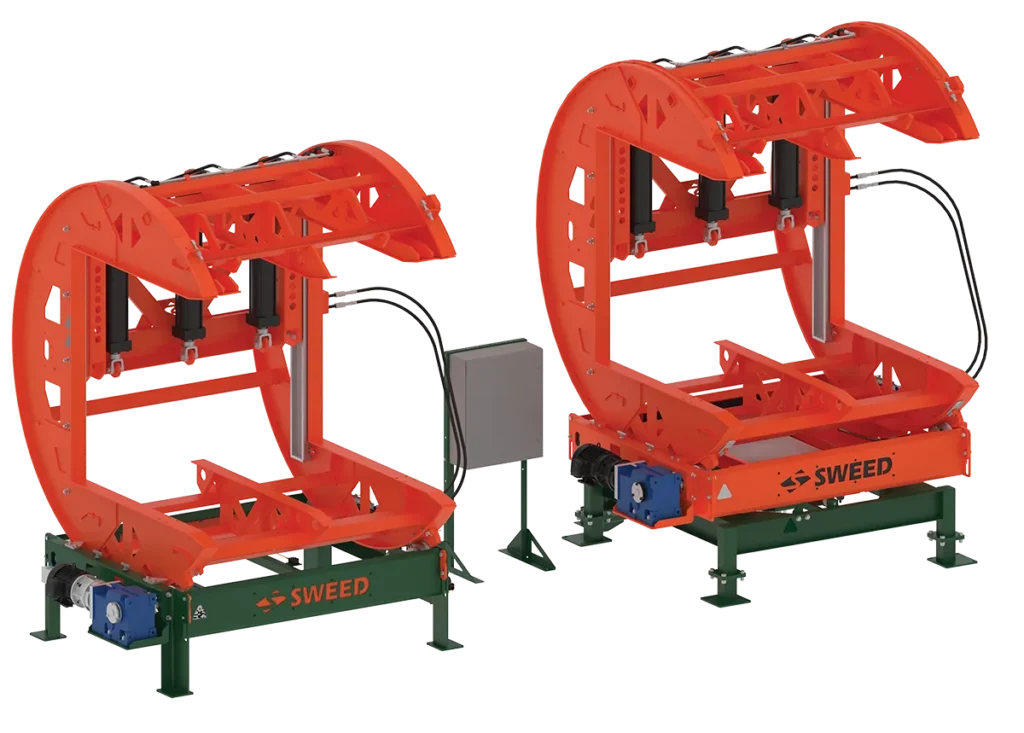

SWEED’s New Standard and Rotating C-Turners: Built Stronger. Built Smarter. Built for Work.

Gold Hill, OR – SWEED Machinery has announced the release of its newly redesigned 64” C-Turner, available in both standard and rotating models. Each model is rated for a 9,000 lb. capacity and built to handle heavy use, long hours, and demanding environments. This redesign is a complete rebuild, developed from years of field experience and direct feedback from operators and maintenance crews.

Key improvements include:

- Thicker Steel Construction: Critical components have been reinforced with heavier gauge steel to stand up to years of punishment.

- Heavy-Duty Chain and Split Sprockets: Upgraded chain sizing and split sprockets make for stronger operation and quicker, simpler maintenance.

- Upgraded Motor and Gearbox: Built with oversized components for more torque, smoother performance, and longer service life under heavy loads.

- Heavy-Duty 3-Cylinder Clamp: Bigger clamping force with a built-in maintenance lockout for added safety.

- Expanded Clamp Travel (64″ to 27″): Handles a wider range of material without the constant adjustments that slows down production.

“This is not just a refresh — it’s a total rebuild, driven by the people who operate these machines every day,” said Kevin Gordon, SWEED’s Sales Director. “We took real-world feedback and made it stronger, easier to maintain, and built for less downtime.”

SWEED Machinery has engineered veneer and panel handling and other material processing equipment for 70 years. Based in Gold Hill, Oregon, SWEED designs and builds rugged systems trusted by mills, manufacturing plants, and industrial operations around the world. Visit our About page to learn more about SWEED’s commitment to U.S. manufacturing and innovation.