Category:

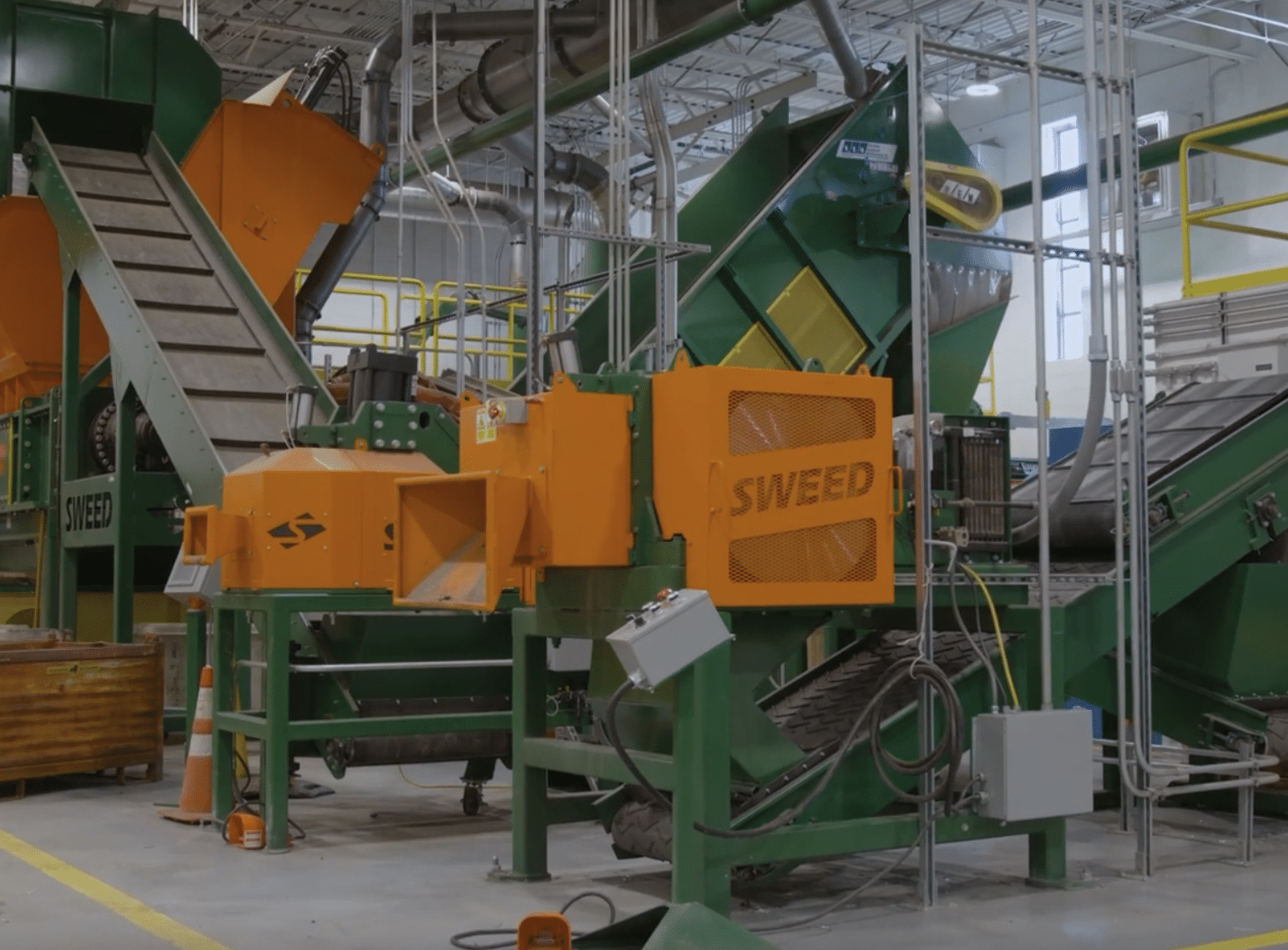

Recycling Systems

Machine type:

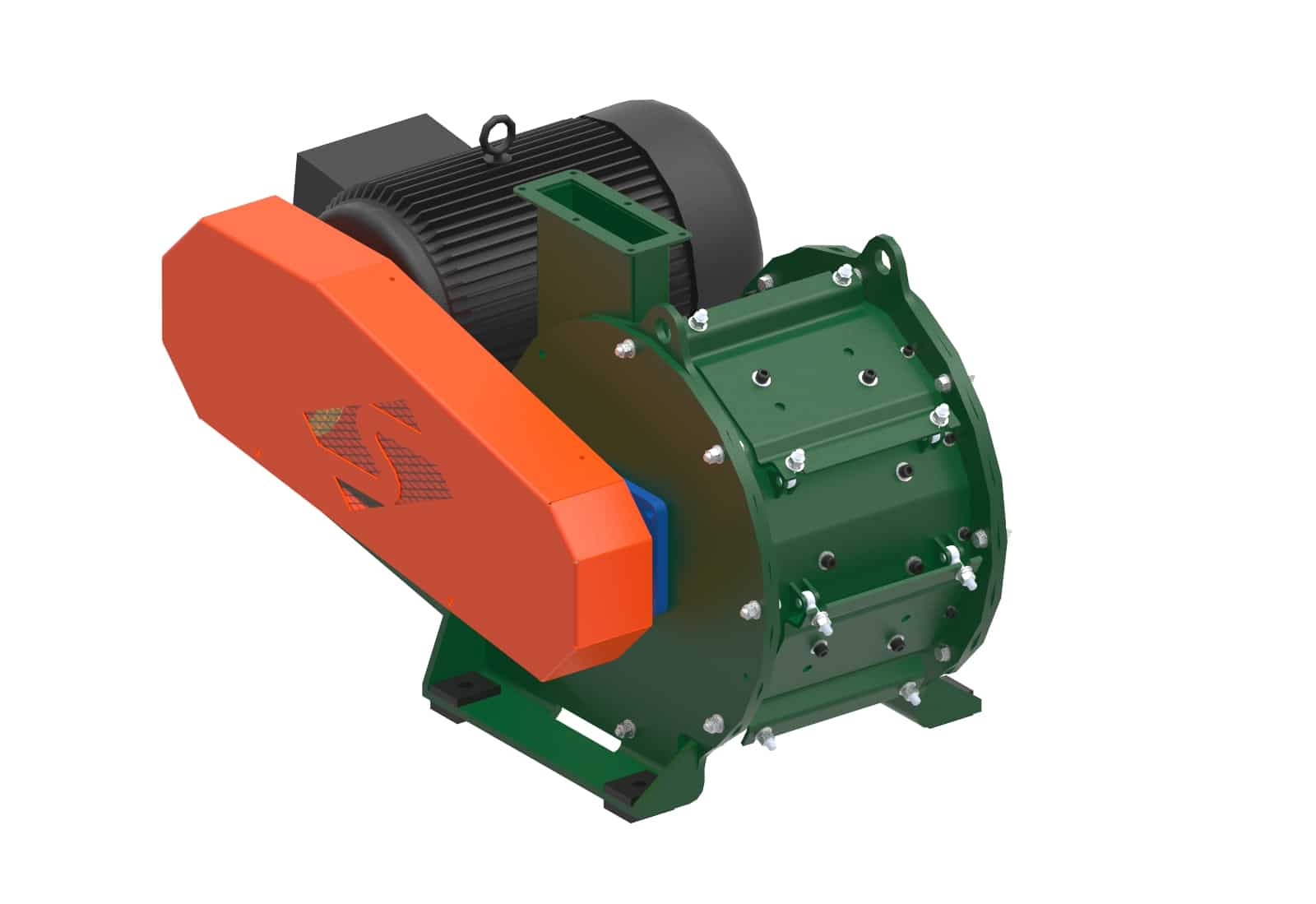

Turbo Mill

Turbo Mill: TM Series

SWEED Turbo Mill: Streamlined Copper Wire Separation Innovation

SWEED’s Turbo Mill is a screenless processor that effectively and efficiently processes #2 copper wire and other fine wire, making it easier to separate.

Traditional fine wire tends to trap plastic, making separation challenging, but the Turbo Mill eliminates this issue. The Turbo Mill’s innovative approach to liberating copper from plastic is a game-changer. Through a dynamic process of tumbling and pulverization, it rapidly removes insulation, creating small copper pellets that flow freely, ensuring effortless separation from plastic. This process significantly increases copper recovery, provides a purer end product, and allows for more throughput.

SWEED’s Turbo Mill is a compact yet impactful addition for any company handling #2 wire. Its cutting-edge technology and user-friendly design make it a must-have for companies looking to optimize copper recovery, increase purity, and boost their bottom line.

Ease of use is a hallmark of SWEED’s machines, and the Turbo Mill is no exception. Available in power options ranging from 40 to 150hp, it seamlessly integrates into existing systems.

Category:

Recycling Systems

Machine type:

Turbo Mill

Construction Features

SWEED’s turbo mill boasts a robust design and seamless integration capabilities, optimizing wire and cable separation with its innovative technology. It efficiently processes fine copper wire, enhancing material recovery and reducing system maintenance, all within a durable construction.