Category:

Recycling Systems

Machine type:

Chopping Line

Sweed Wire Chopping Lines

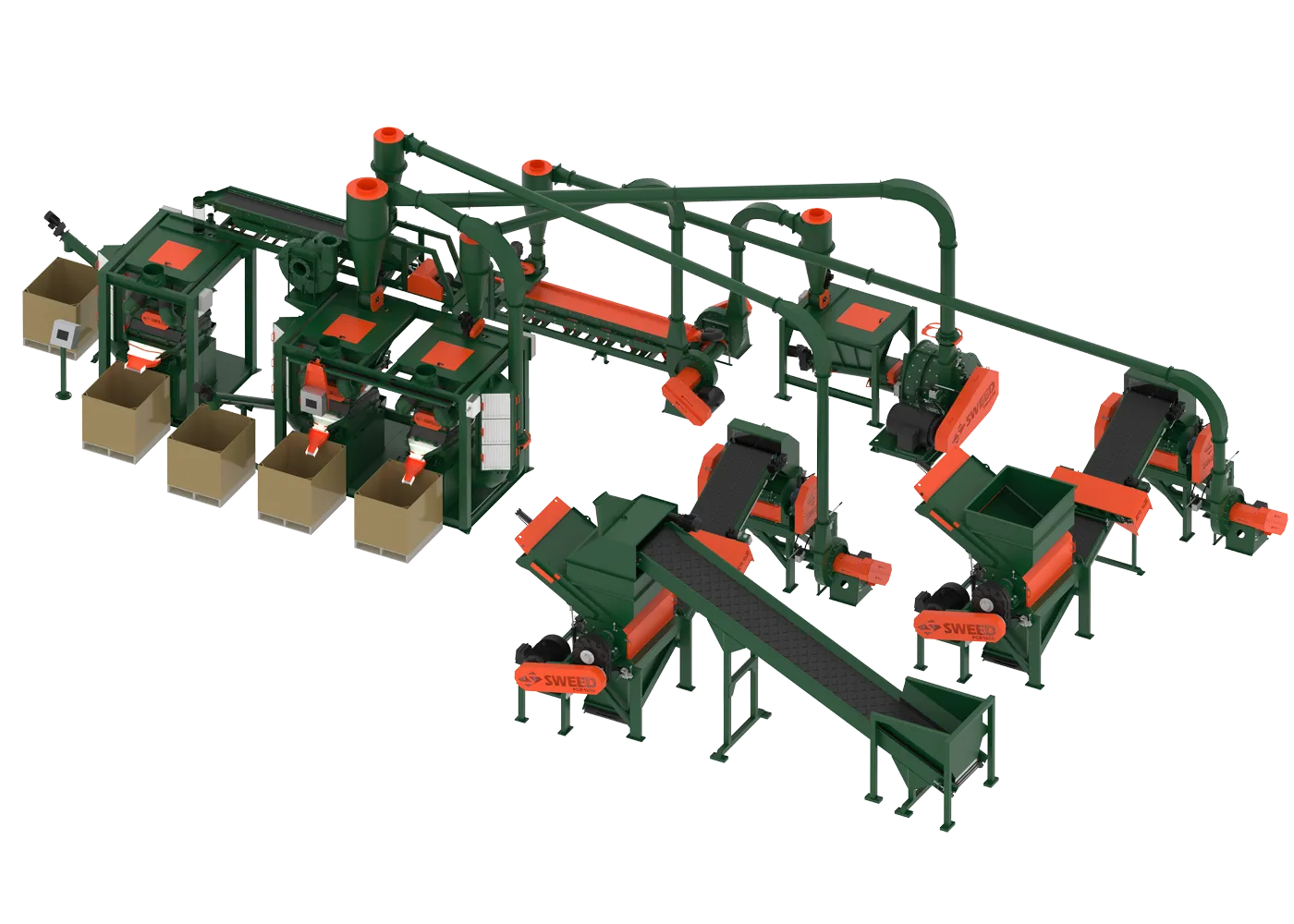

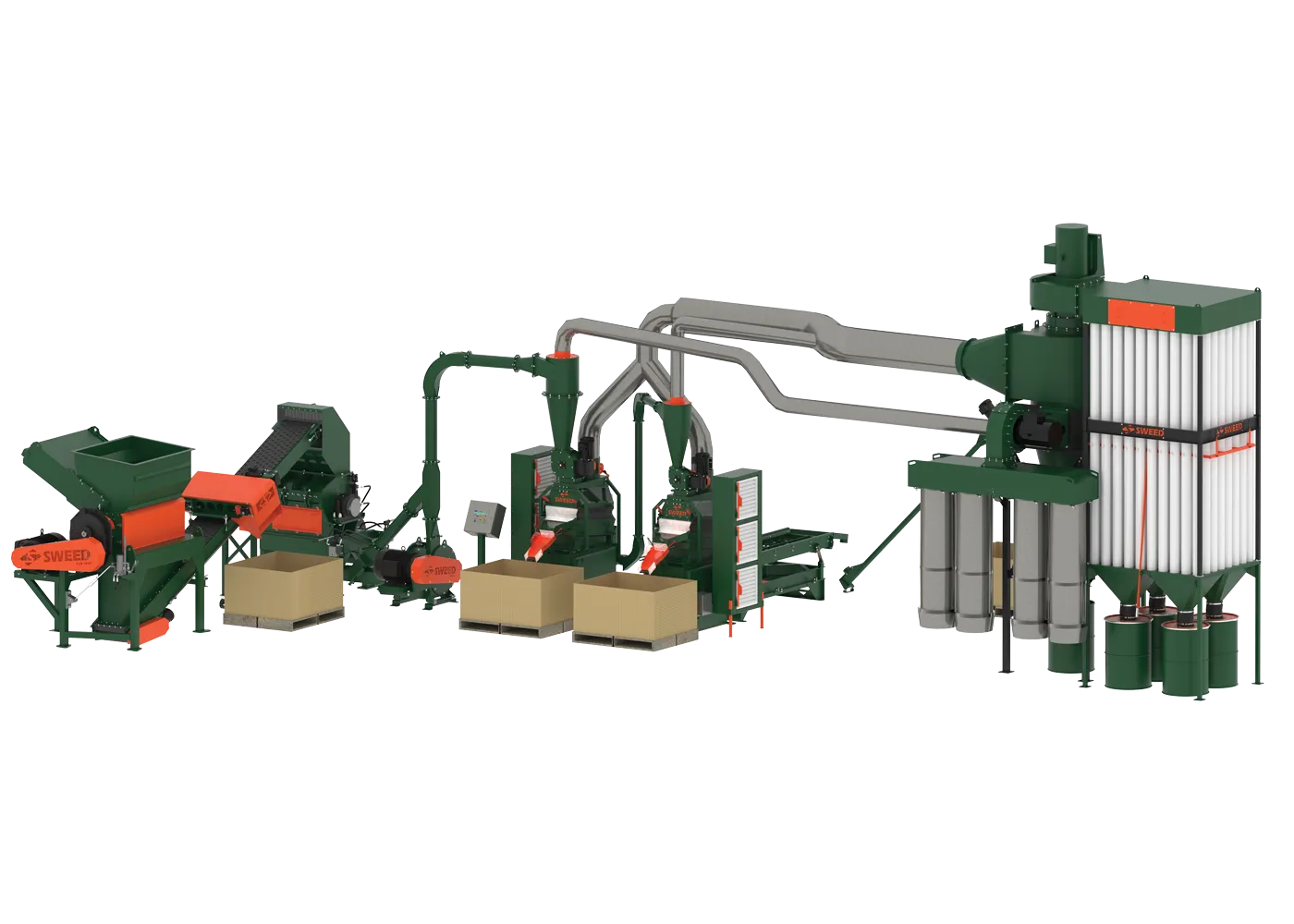

Custom Chopping Line Solutions

SWEED specializes in crafting customized chopping lines that precisely match your specifications and material.

Our robust processors are meticulously engineered for efficient recovery of copper and aluminum in operations of varying volume, be it low or high, and are engineered to handle a wide range of materials, including power and communication cables, ASR, ACR, ACSR, BX Cable, wire harnesses, and more, accommodating varying processing volumes. We provide tailored solutions based on factors such as available space, material types, throughput requirements, and purity standards.

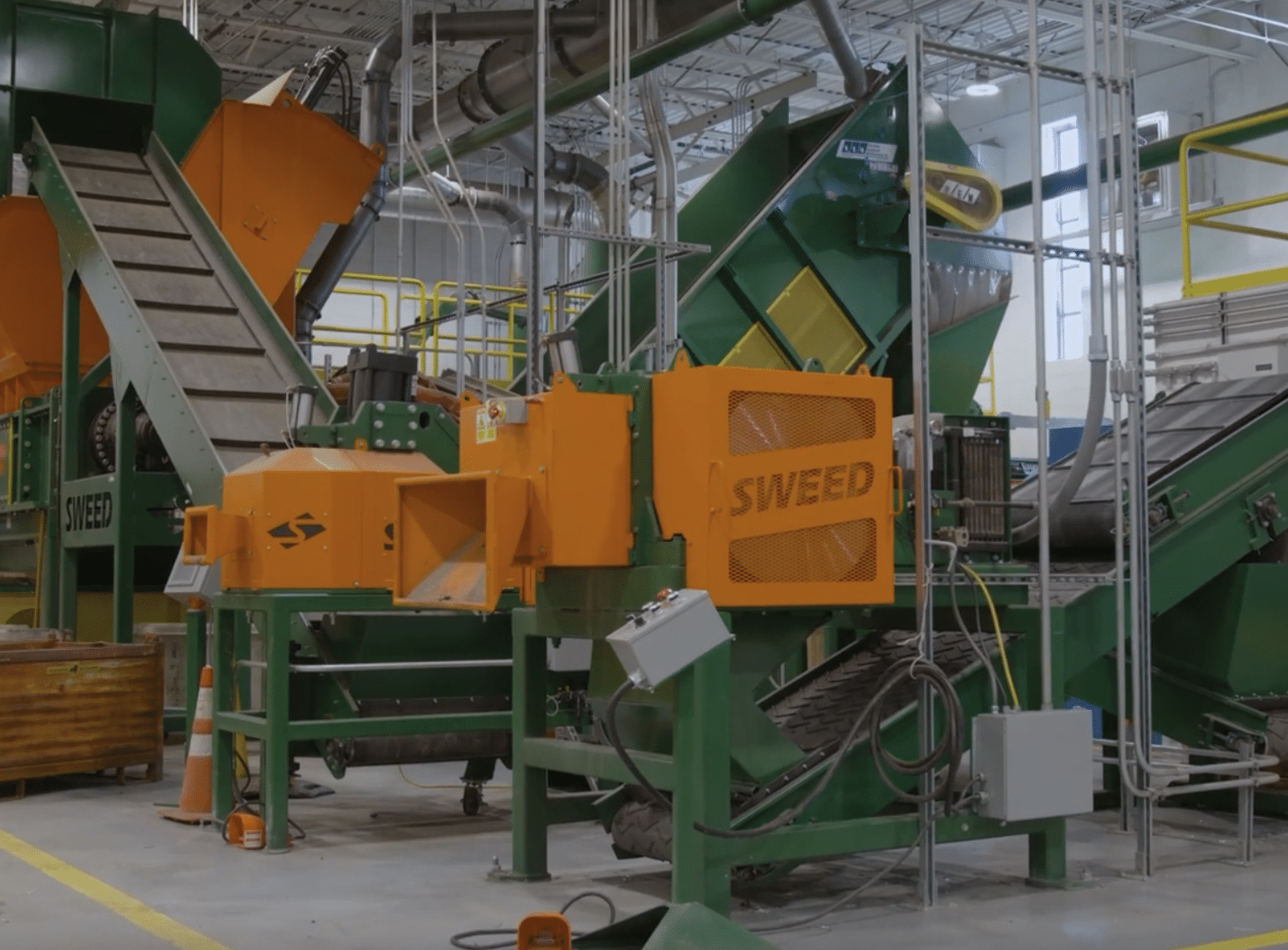

SWEED excels in enhancing existing systems.

For example, one customer significantly improved their throughput and capabilities by integrating a SWEED wire chopping line using some of their existing components. This upgrade enabled them to transition from processing 1,000-1,200 pounds per hour to 3,000-6,000 pounds per hour (and up to 8,000 pounds per hour, depending on the material), efficiently separating copper and aluminum in a single pass.

Another customer undertook a substantial wire chopping line project with strict safety requirements. SWEED collaborated with the customer and their contractors to deliver a recycling system that exceeded safety specifications. This system effectively recovered scrap copper and aluminum from various cable types, including bare aluminum wire, ACSR, jacketed aluminum and copper cable, URD, MCM, green wire, #1 ICW, #2 ICW, and more. SWEED’s tailored solution ensured maximum recovery while adhering to regulatory standards and considering factors such as footprint, scrap materials, production capacities, and purity requirements.

SWEED’s chopping lines are versatile and accommodate various materials.

Optional equipment enhances performance, and flexible expansion options allow for the addition of components like the SWEED 5703XHD rotary shear to despool cable from a reel or the inclusion of a SWEED Prechopper on the front end to increase downstream throughput. With SWEED, you can configure your system to operate in parallel or in series, offering both single and multiple separation air table system options, as well as additional refining equipment, to ensure efficient processing tailored to your specific needs.

Another detail that sets SWEED apart is our commitment to making maintenance easy and efficient. Our designs prioritize easy access to equipment, simplifying the process of performing essential maintenance tasks. This not only minimizes downtime but also ensures your system operates at peak performance throughout its lifespan.

SWEED takes pride in our American heritage, designing, manufacturing, and supporting equipment in the United States. This commitment ensures the highest quality and reliability, with readily available consumable parts to reduce downtime and ensure the smooth operation of your facility.