Category:

Wood Products

Machine type:

Veneer Stackers

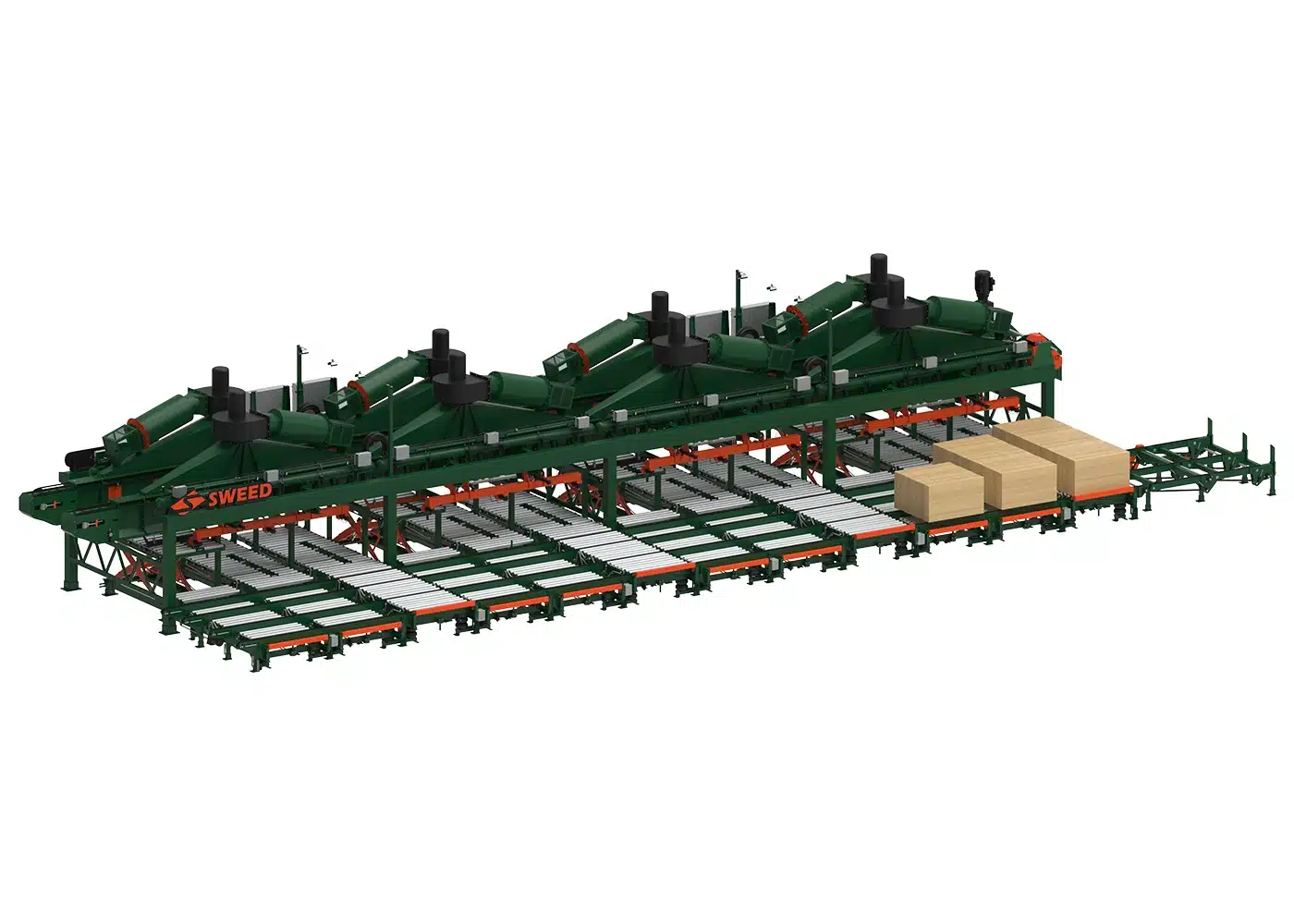

Versatile Veneer Stacker

Everything You Should Expect in a Stacker.

The SWEED Versatile Veneer Stacker is a unique and innovative approach to veneer stacking. It provides the perfect solution for stacking one size of veneer, or any combination of 4-, 8-, 9-, and 10-foot veneer.

The core functionality of this versatile stacker is based on proven technology, with one major innovation: it uses a split moving plenum that allows the stacker to easily adjust to multiple lengths of veneer, consequently making traditional stackers (with multiple plenums) obsolete. Historically, stackers intended for various lengths of veneer utilized three plenums, adding to the number of belts, knock-offs, valves and more, which resulted in higher up-front costs, and were more expensive to maintain. SWEED’s groundbreaking adaptable solution keeps the stacker concept simple and makes changeovers (from one length to the next) as easy as a push of a button, in less than a minute.

SWEED’s innovative solution to multiple lengths also applies to standard stacking applications. The split-plenum design dramatically improves accessibility, which allows for internally located knock-offs rather than the traditional exterior mounted cylinders. This results in a more reliable, better balanced knockoff interface with the veneer, thus resulting in higher stack quality.

SWEED’s Versatile Veneer Stacker is the only one in the industry that uses a simple approach to solve a traditionally complex problem. This patented design, coupled with SWEED’s engineering expertise and stateside support, result in a superior solution at a competitive price.

Construction Features

At SWEED, we carry forward the Jeddeloh brothers’ legacy of relentless commitment to construction, craftsmanship, durability, and reliability in our wood products equipment. Designed to perform 24/7, our solutions are renowned for their robust construction, thriving in demanding environments. Our material handling solutions seamlessly enhance productivity and safety, providing the flexibility to optimize your operations, all while maintaining the enduring tradition of exceptional quality that defines SWEED.