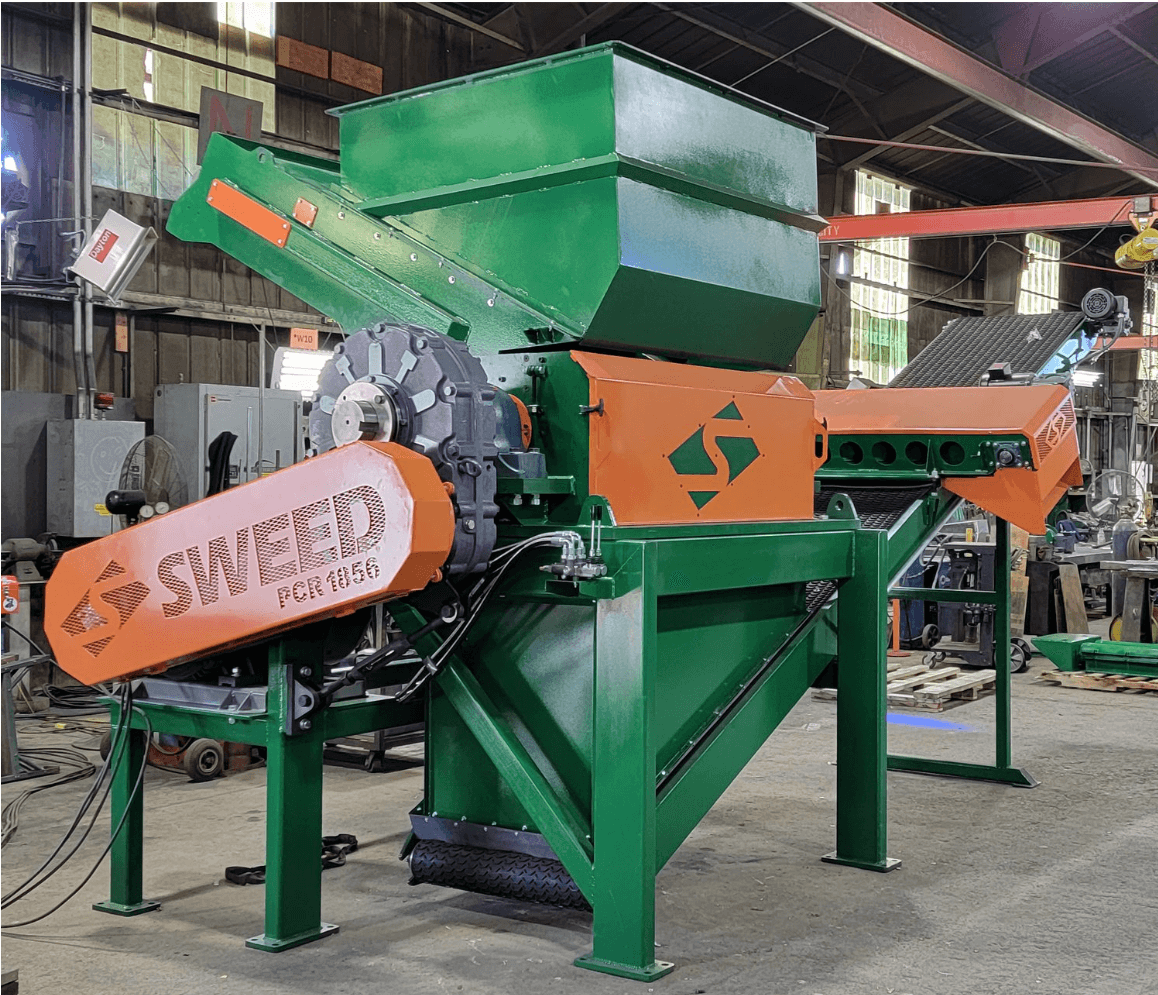

New Single Shaft Shredder

As seen in Recycling Product News magazine

NEW SINGLE-SHAFT SHREDDER FEATURES LESS KNIVES AND AN INCREASED CUTTING CAPACITY

Sweed has added the PCR1856 single-shaft shredder to its line of recycling equipment.

The new shredder is the largest in Sweed’s PCR series and features a 125 horsepower motor, 18-inch rotor diameter, 56-inch rotor length, and a 50- by 57-inch cutting chamber, functioning as either a primary or secondary processor in high volume applications.

The PCR1856 features a more extensive knife profile, which delivers a bigger bite into the scrap and enables larger material to be pulled into the machine quicker and more efficiently. The larger knives allow the PCR1856 to process a wide range of bulky scrap, especially wire and cable. The PCR1856 also features fewer knives than its predecessor, 54 instead of 76, but still has double the cutting capacity. Fewer knives allow for quicker knife changes and lower maintenance costs.

Additionally, the Sweed PCR1856 includes a hydraulic ram to keep material engaged with the rotor to optimize throughput. The unit can stand alone or operate in any existing chopping line and can adjust its speed and ram parameters to optimize a system when tied into a downstream processor.