Recovery Systems For Maximum Value

The Real Cost of Inefficient Aluminum Recovery

If your aluminum recovery chopping line isn’t engineered to handle scrap effectively, you’re leaving money on the table every single day.

- Contaminated output lowers resale value

- Incomplete separation leads to aluminum mixed with plastics or copper

- Manual sorting adds cost, time, and risk

- Lightweight fines are often lost or discarded

Every pound of recoverable aluminum left in your waste stream is lost revenue. SWEED’s aluminum recovery systems are designed to minimize loss, boost purity, and help you get the full value out of your scrap.

The SWEED Difference

Increase Your Recovery Value

SWEED aluminum recovery systems are built to last, engineered for flexibility, and supported by U.S. based teams who know your industry. Whether you're recycling insulated aluminum wire, separating nonferrous metals, or processing bulk telecom scrap, SWEED gives you the tools to recover material with higher purity and higher profit.

- High-purity separation of aluminum and copper

- Systems scaled from 2,000 to 25,000+ lbs/hr

- Proven performance on ACSR (Aluminum Conductor Steel-Reinforced), ASR (Automotive Shredder Residue), ICW (Insulated Copper Wire), IAW (Insulated Aluminum Wire), and mixed wire bundles

- Modular & expandable as your needs grow

- Made and supported in the USA

How Aluminum Recovery Works

Intake & Preprocessing

The Challenge

Aluminum wire often arrives coated, bundled, baled, or mixed with steel or plastic. Manual prep is time-consuming and risky, but without it, unprocessed material can damage downstream equipment.

The Goal

Transform unmanageable aluminum scrap into clean, consistent feedstock. That means cutting long cable, removing jackets, and shredding bundled wire before granulation with automated ferrous removal built in.

SWEED Solutions

- Cable Cutters (CA Series): Cut large-diameter aluminum cable and mixed bundles down to manageable lengths.

- Sheathing Slitters (SS6K): Strip heavy outer jackets from aluminum-clad cable.

- Prechoppers (PCR Series): Single-shaft shredders ideal for ASR, insulated wire, and mixed nonferrous scrap.

- MS Series Shredders: Tackle dense telecom bundles and ACSR (Aluminum Conductor Steel-Reinforced) with ease.

- Magnetic Cross-Belts: Automatically remove ferrous material before downstream processing.

Chopping & Granulation

The Challenge

Lightweight aluminum wire can nest or flatten instead of liberating. Inconsistent chopping results in incomplete separation or excessive fines and reduces separation efficiency. Without precision granulation, recovery suffers.

The Goal

Efficiently chop and size aluminum wire into uniform granules ready for density separation. All while maintaining high throughput and minimizing fines loss.

Sweed Solutions

- Granulators (SG Series): High-speed aluminum wire granulators for clean, consistent sizing.

- Turbo Mills (TM Series): Optional upgrade for processing fines or complex, mixed-metal streams.

- Scrap Choppers (5503 / 5703 XHD): Built for linear aluminum cable and ACSR spooled on reels.

- Metering Feeders & Shakers: Deliver even, controllable flow to downstream separation.

Separation & Purification

The Challenge

Aluminum’s lightweight nature makes separation from plastic and steel challenging, especially when mixed with copper or fines. Without advanced separation, contamination lowers resale value and can force reprocessing, which can cause material loss.

The Goal

Cleanly separate aluminum from insulation, plastics, and other metals while minimizing manual sorting and labor.

Sweed Solutions

- Air Tables (G Series): Density-based separation for high-purity aluminum recovery.

- Zig-Zag Separators: Remove film, fluff, and lightweight contaminants from granules.

- Magnetic Head Pulleys & Stainless Steel Separation: Eliminate steel or residual contaminants.

- Dust Collection Systems (SDC Series): Maintain air quality and OSHA compliance.

- Auger & Sifter Outfeeds: Streamline and direct final material routing.

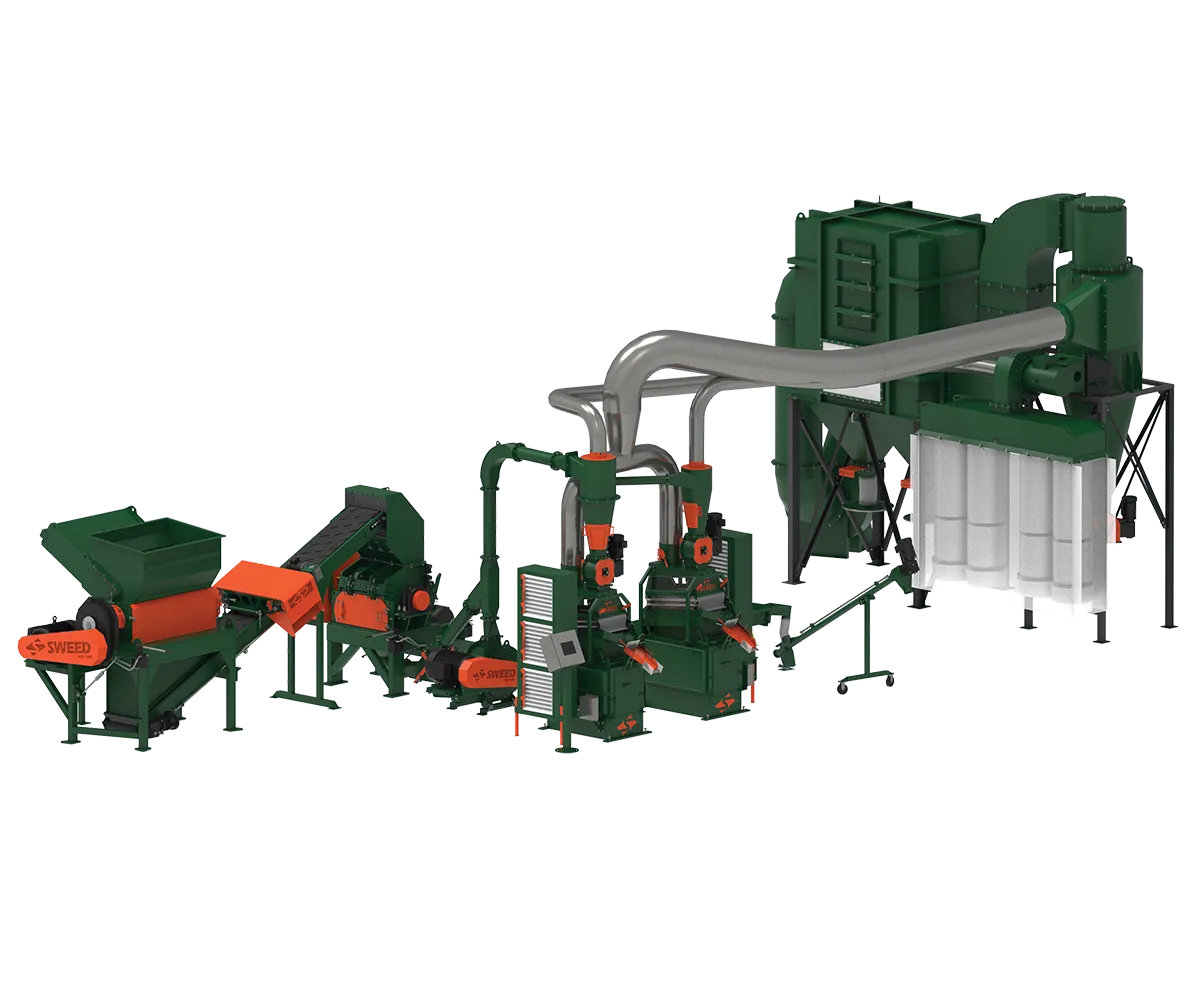

Turnkey Aluminum Recovery Systems

Not every operation needs a fully customized aluminum recovery line, but some do. SWEED offers both. If you're ready to get up and running quickly, our pre-engineered systems like the S2000+ Series deliver fast payback and proven results. If your needs are more complex, we’ll design a fully custom system to match your specific throughput, material mix, and facility layout.

S2000+ Wire Chopping Line

The S2000+ is SWEED’s ready-to-deploy standard aluminum and copper recycling system. Designed to process up to 2,000 lbs per hour, it handles insulated aluminum wire and copper scrap simultaneously in a single pass, using a dual-air table setup for clean, efficient separation.

The system includes:

- Prechopper

- Granulator

- Turbo Mill

- Dual 3G air tables

- Dust collection and auger discharge

- Control cabinet with remote access (optional)

If you’re looking for a turnkey aluminum wire chopping line that integrates easily into your operation and delivers clean metal output, the S2000+ is your fastest path to ROI.

ACSR Processing Systems

High-volume solutions for aluminum conductor steel-reinforced cable.

SWEED’s ACSR systems are built around powerful linear scrap choppers like the 5703 XHD, paired with magnetic separation to cleanly divide aluminum from ferrous strands.

- Designed to handle high volumes of ACSR cable

- Magnetic cross-belt separators for effective steel removal

- Available in skid-mounted or modular configurations

- Ideal for utility, telecom, and scrap processors receiving material on reels