Turn Residual Scrap into Revenue

At SWEED, we understand that every pound of copper matters. Tailings, also known as copper residue or copper fines, are a byproduct of previously processed material. Though this scrap has resale value, its worth is diminished when it’s contaminated.

That’s why we developed the Tailings Clean Up (TCU) System: a turnkey solution to separate, clean, and reclaim high-purity copper from contaminated tailings elevating your revenue and operational efficiency.

Quick ROI

Fast Payback, Proven Results

With efficient copper recovery and low operating costs, the TCU System is built for fast financial return, often delivering full ROI in just one year. Even operations with lower copper content frequently achieve full payback within two years of installation.*

*Based on typical customer results. Individual ROI may vary.

Self Metering Hopper

The open-top hopper is designed for simple and versatile feeding, allowing operators to load material easily with a forklift, or directly from the main system via conveyor or auger. This flexibility streamlines loading procedures, reduces handling time, and integrates seamlessly with automated processes, ensuring continuous and efficient material flow into the system.

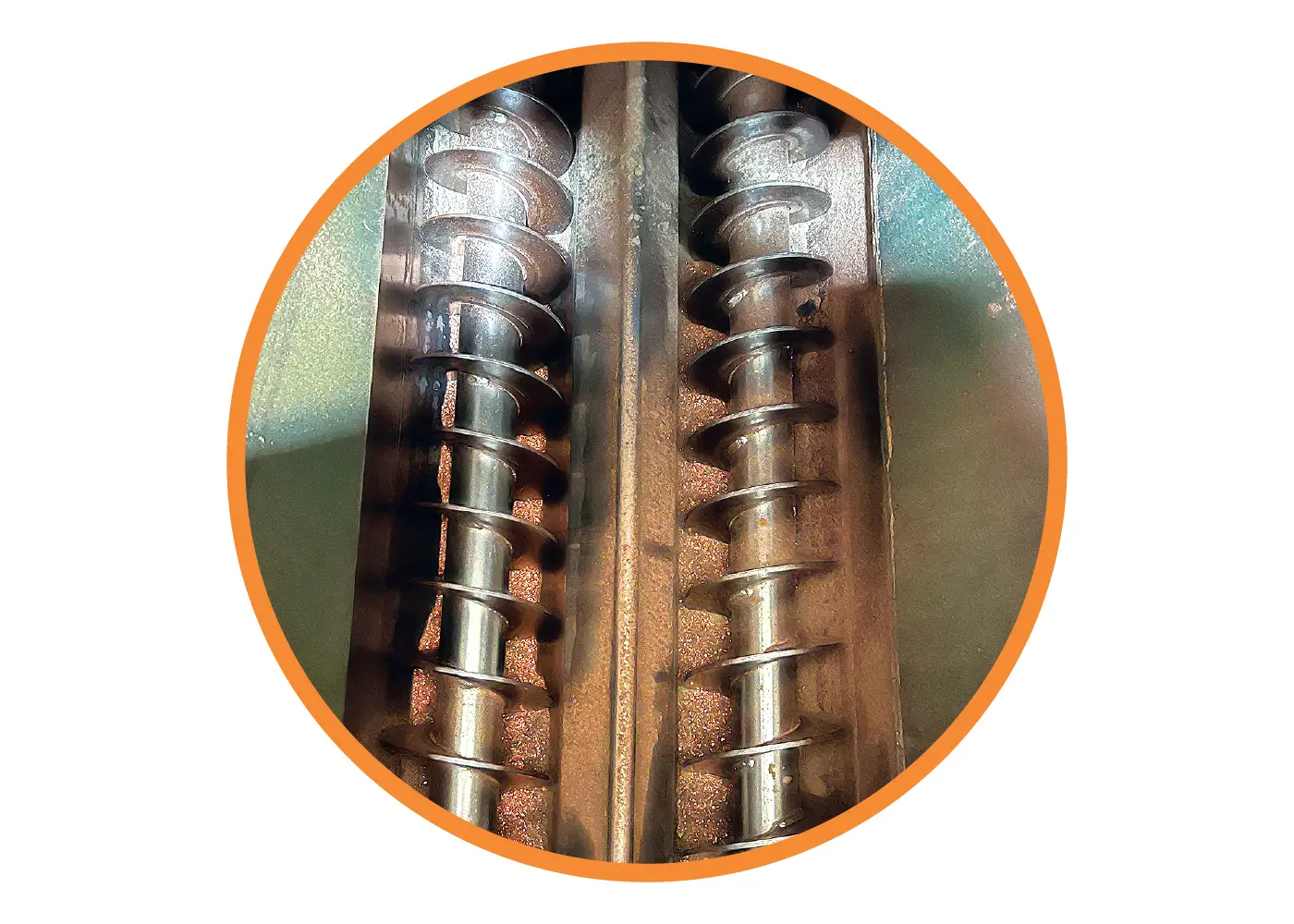

SWEED Turbo Mill

The Turbo Mill efficiently liberates fine copper hairs from insulation and other contaminants, transforming mixed material into clean, separated streams. This process enhances copper purity and recovery, improves downstream separation, and increases the resale value of recovered scrap.

Clean Output

The final separated output delivers two clean, high-value streams: copper ready for resale at premium rates and contaminant-free insulator. This clear division maximizes material value, reduces waste handling costs, and ensures the recovered copper meets market quality standards for optimal profitability.

The SWEED Solution

Built for flexibility, performance, and ease of integration, the SWEED Tailings Clean Up System delivers a practical path to higher copper recovery without overhauling your operation. Here’s what sets it apart:

- Skid-mounted for easy installation

- Open top self-metering hopper for easy loading by forklift, conveyor, or auger

- Equipped with a turbo mill that liberates fine copper from contaminants for higher purity recovery

- Available in models that handle up to 2, 4, and 6 thousand pounds per hour

- Runs alongside your existing line and can be operated by the same crew, no added headcount or shift changes needed

- ROI in as little as 12 months*

*Based on typical customer results; individual ROI may vary.

Learn More >

Is There Money in Your Material?

Let us run a sample of your tailings. We’ll show you exactly how much you’re giving away.

Request a Quote >