Solution for Recovering Copper from Low-Yield Wire

As Seen in Wire and Cable Technology International Magazine

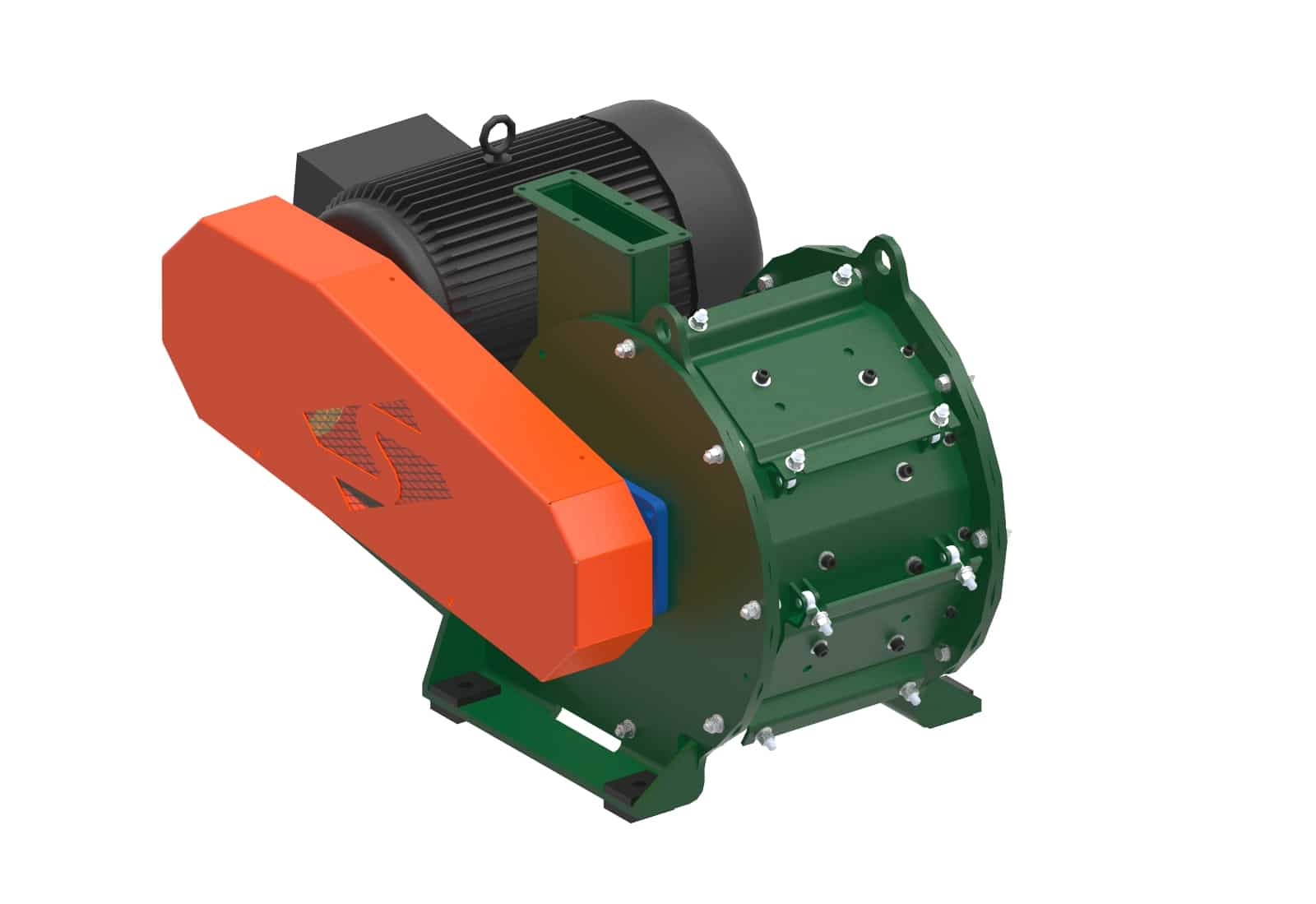

Sweed Machinery, Inc., Gold Hill, OR, USA is in the business of finding innovative solutions for its customers’ needs. Melissa Tally, Sweed’s Marketing Manager, reports, “When we began seeing an increase in low-yield copper recovery inquiries two years ago, we decided to design and manufacturer our version of a machine that could address the gap our customers were experiencing. In true Sweed fashion, this design allows for more adjustment of the process, while being a much sturdier piece of equipment.”

“Our Turbo Mill effectively and efficiently processes #2 copper wire and other fine wire, making it easier to separate,” says Chris Salyer, Sweed Engineering Director. “Before it hit the market, the primary source for customers in the USA for a turbo mill was via international manufacturers. We saw an opportunity to offer our world-class engineering, service/technical support.”

How the New Technology Works

To separate the copper from the plastic surrounding it, the Turbo Mill beats the material around, tumbling it over and over to pulverize any remaining insulation. This friction rips the plastic away from the copper wire, which is balled into tiny pellet-like pieces. In this shape, the balled copper “flows” freely like fine sand, allowing it to separate easily from the plastic; straight fine wire will nest and entrap plastic making it difficult to separate effectively. The Turbo Mill provides many distinct benefits in the copper liberation process.

“Because it makes the balled copper easier to separate from the plastic, the Turbo Mill increases copper recovery,” Salyer says. “Recovered copper also has an increased purity because the process that removes it from the plastic ensures that the two materials are completely separated. Best of all, it increases your processing capability. Without a Turbo Mill, in Sweed’s entry-level chopping line someone might use a 1/8” screen, which allows for 1500 to 2000 lb of processing per hour. With a Turbo Mill, you can use a larger 3/16” or 1/4” screen, which more than doubles your throughput and lets you process 4000 to 5000 lb of material every hour.”

That increase is also reflected in the user’s bottom line. With a higher quantity of purer copper, more scrap can be reused or sold at a higher value.

Easy System Integration

The Turbo Mill, like every Sweed machine, is built with usability as a priority. With a line that ranges from 40 to 150 HP, Sweed’s Turbo Mill can easily integrate into any existing system.

“We care a lot about providing high-quality service, which is why we will come out and help customers set up their new machines,” Salyer says.

That ease of use also extends beyond installation – once the Turbo Mill is integrated into the system, it stays simple to run and maintain.

“It usually feeds right from the granulator, and only needs standard maintenance every million pounds or so,” says Salyer. “Once it’s up, it just runs itself. It just goes.”

With many benefits and easy installation / maintenance, Sweed’s Turbo Mill is a must-have for any company that processes #2 wire. It’s a small unit with a big impact.