How Sweed’s Original Gang Saw Forged a Future of Innovation and Quality

In the early 1950s, three brothers bought a piece of land in Southern Oregon to start a sawmill and logging business. As talented engineers with a great deal of creativity, they ran all of the mill’s machinery while looking for ways to make their production more efficient and effective. After finding no machines on the market that matched their ideas and specifications, they set out to build one themselves.

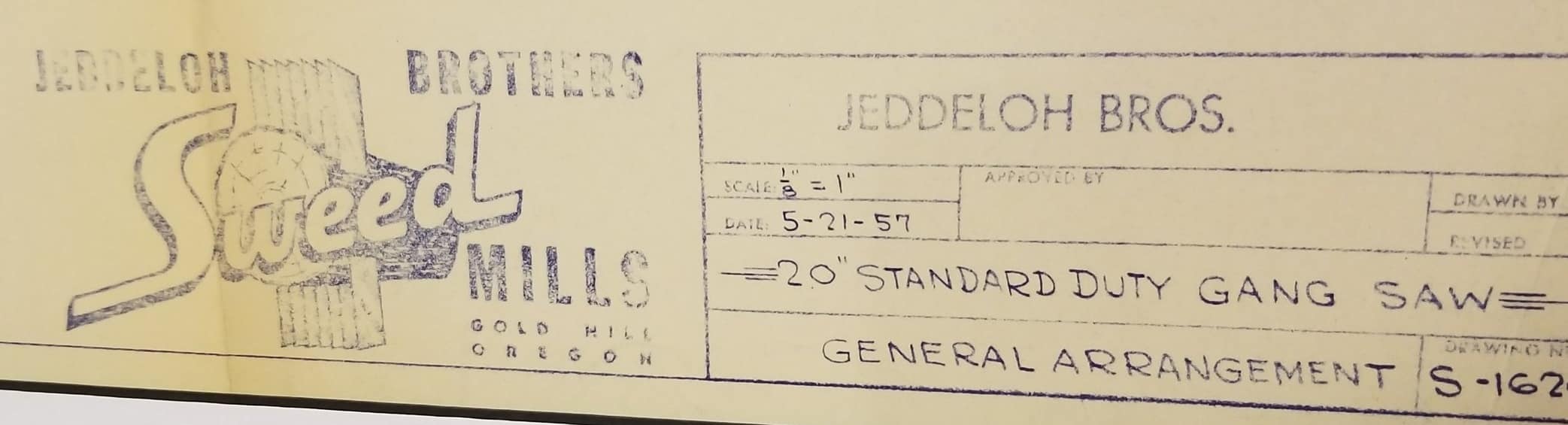

That decision – to use their own ingenuity to fill an industry need – caused the Jeddeloh brothers to create a gang saw that processed timber logs in one pass, a huge innovation at the time. “We found the original design for that gang saw,” says Scott Ashpole, Shareholder/Sales at Sweed Machinery. “It did the work of four men and totally changed how the Jeddeloh brothers did business.” Word began to spread that the brothers could build their own machinery, and people started to submit requests for various machines. The machinery division was born out of those innovations, and the Jeddeloh brothers started down the path that would ultimately lead their business, the Jeddeloh Brothers Sweed Mill, to become today’s Sweed Machinery.

With their new machinery division, the Jeddeloh brothers’ pioneering spirit only grew. As plywood mills were being built throughout the Pacific Northwest in the 1950s and 1960s, the machinery division began building panel and veneer handling equipment. “Plywood was a new way to look at lumber and wood,” Ashpole explains. “[The Jeddeloh brothers] saw that part of the industry was growing, so they focused on it.” Their panel and veneer handling equipment garnered such wide recognition for its workmanship and innovation that the Jeddeloh Brothers Sweed Mill ceased other business functions to focus solely on meeting the demand for their machines. “Pretty soon, they were shipping train carloads of plywood equipment all over the country,” says Ashpole.

Over the years, much changed: they eventually sold the mill, the machinery division diversified its output, and the business’s name became Sweed Machinery. But while the industry and the business have morphed and grown, the culture of innovation forged when the Jeddeloh brothers built that first gang saw persists today. “We continue to set the bar on panel and veneer handling solutions,” says Ashpole. Just recently, Sweed crafted and patented Smart Pause technology for veneer dryers. “The technology allows the dryer to stay completely full if someone misses a feed. This makes it so that veneer dryers don’t lose heating efficiency or drying consistency, which improves our customers’ efficiency and ends up saving them money.”

These innovations also created Sweed’s scrap processing division. Sweed’s first scrap chopper was designed to process the steel strapping on plywood for easier and safer disposal that also saved space. The recycling division has since become Sweed’s largest division, with a whole series of machines and equipment that can process and separate a wide scope of different materials both linearly and in bulk. “Our customers all have different situations, and we often have to engineer and innovate to find solutions for their products and needs,” says Ashpole. Because of these customer-centric innovations, there is now a Sweed scrap chopper on every continent except Antarctica.

Innovation is only one piece of the puzzle, though. None of Sweed’s growth, success, or continued opportunity to innovate would be possible without a commitment to producing quality machines that last. “Sweed’s heritage is in mill equipment where all of the machines were designed to run 24/7,” Ashpole explains. “To keep up with such a schedule, they had to be robust, durable, and high quality.” Because of this heritage, Sweed believes customers should be able to use their machines for as long as possible, which builds trust and keeps customers coming back for other innovative solutions. “In recent years, a lot of companies have let go of quality standards – some machines only last 3-5 years. We’ve noticed this across our entire product mix, and especially when comparing our line of scrap choppers and wire chopping systems to others. Sweed hasn’t followed that trend.” says Ashpole. “I have had customers call in for parts for the first time 10 or 20 years after buying their Sweed machine. When people see our machines, they know that they’re really well-built and that they’re going to last.”

Today, Sweed is much more than a gang saw. With extensive lines of veneer and panel handling equipment, scrap choppers, wire and cable recycling systems, and other scrap processing equipment, the company has grown significantly from the Jeddeloh brothers’ original machine. But the DNA of that gang saw – the innovation that created it and the craftsman’s quality that built Sweed’s reputation for dependability – is still apparent today. “We focus on bringing innovative solutions while never compromising our commitment to bringing robust designs to the marketplace” says Ashpole. “Innovative solutions to help tackle today’s issues with old school quality, reliability, and service.”

So here’s to the gang saw that started it all.