Category:

Wood Products

Machine type:

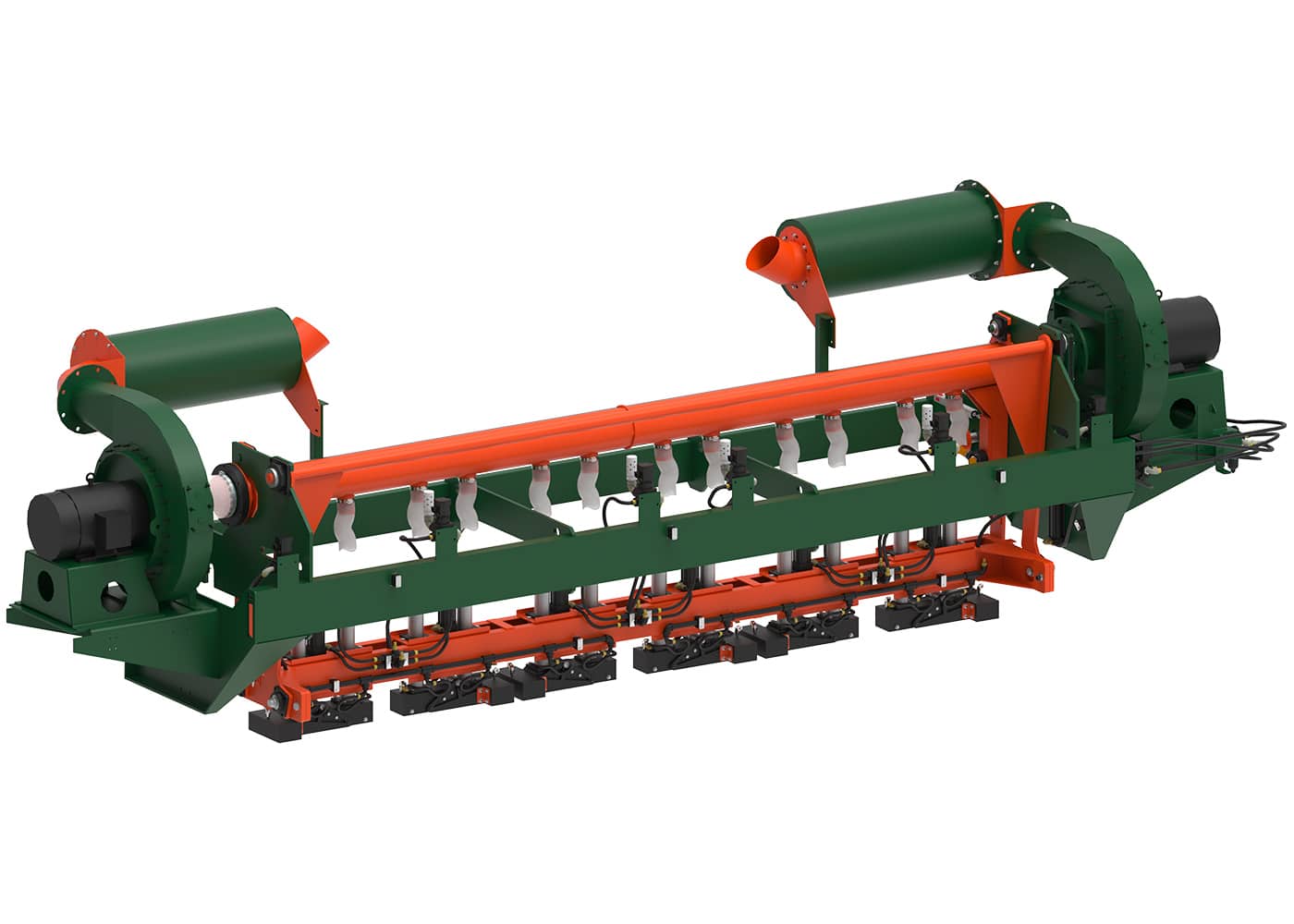

Veneer Dryer Infeeds

Vacuum Feeder Peel Cups

Virtually Eliminate Double Feeds and Increase Vacuum Feeder Efficiency.

SWEED’s new Vacuum Feeder Peel Cups are an exclusive design, utilizing a patented approach for gripping and feeding green veneer into the dryer.

This method dramatically reduces feeding multiple veneer sheets, commonly known as “doubles.” It also reduces labor and allows for more consistent moisture content levels resulting in increased dryer efficiency.

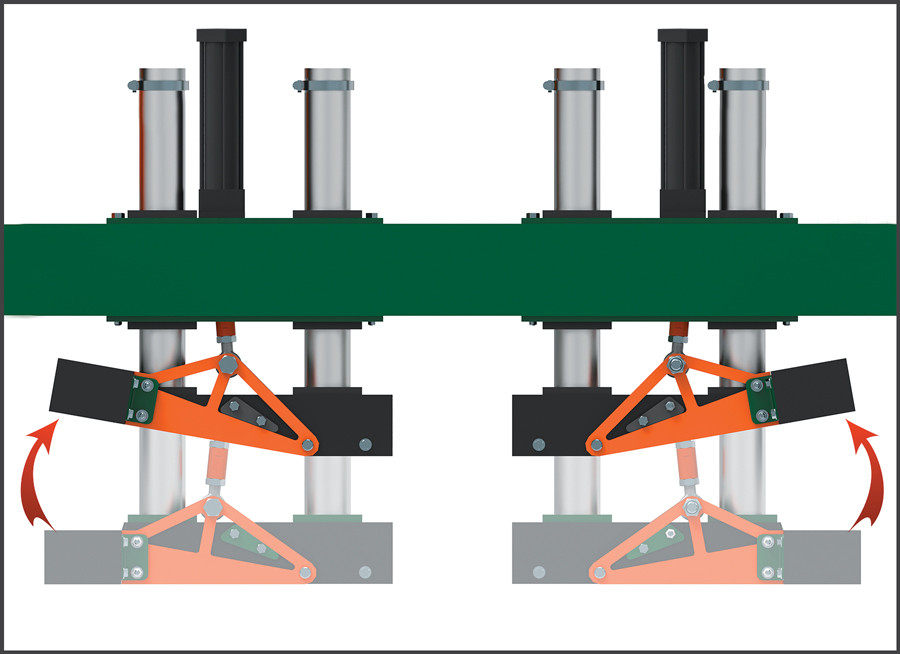

Traditional dryer feeders have vacuum cups that pick the veneer straight up while keeping the sheet flat. The downside of this design is the cup can inadvertently lift multiple sheets at one time, causing double feeds.

When a double occurs, the operator must intervene and separate the sheets. With today’s dryer speeds and throughput requirements, this becomes a near impossible task, resulting in decreased productivity, efficiency, and out-of-spec veneer moisture levels.

SWEED’s new Peel Cups lift the sheet and peel the outside edges from the stack, then pull it into the dryer tipple feeder. The Peel Cups’ lifting process mimics an operator’s efforts to separate two sheets from one another if they become stuck. The emulated process of the cup occurs mechanically, therefore not requiring assistance from the operator. This allows for faster feed speeds and reduced operator fatigue.

SWEED’s new patent-pending Vacuum Feeder Peel Cups are a revolutionary design made for today’s high-speed veneer dryers.

Construction Features

At SWEED, we carry forward the Jeddeloh brothers’ legacy of relentless commitment to construction, craftsmanship, durability, and reliability in our wood products equipment. Designed to perform 24/7, our solutions are renowned for their robust construction, thriving in demanding environments. Our material handling solutions seamlessly enhance productivity and safety, providing the flexibility to optimize your operations, all while maintaining the enduring tradition of exceptional quality that defines SWEED.