Category:

Wood Products

Machine type:

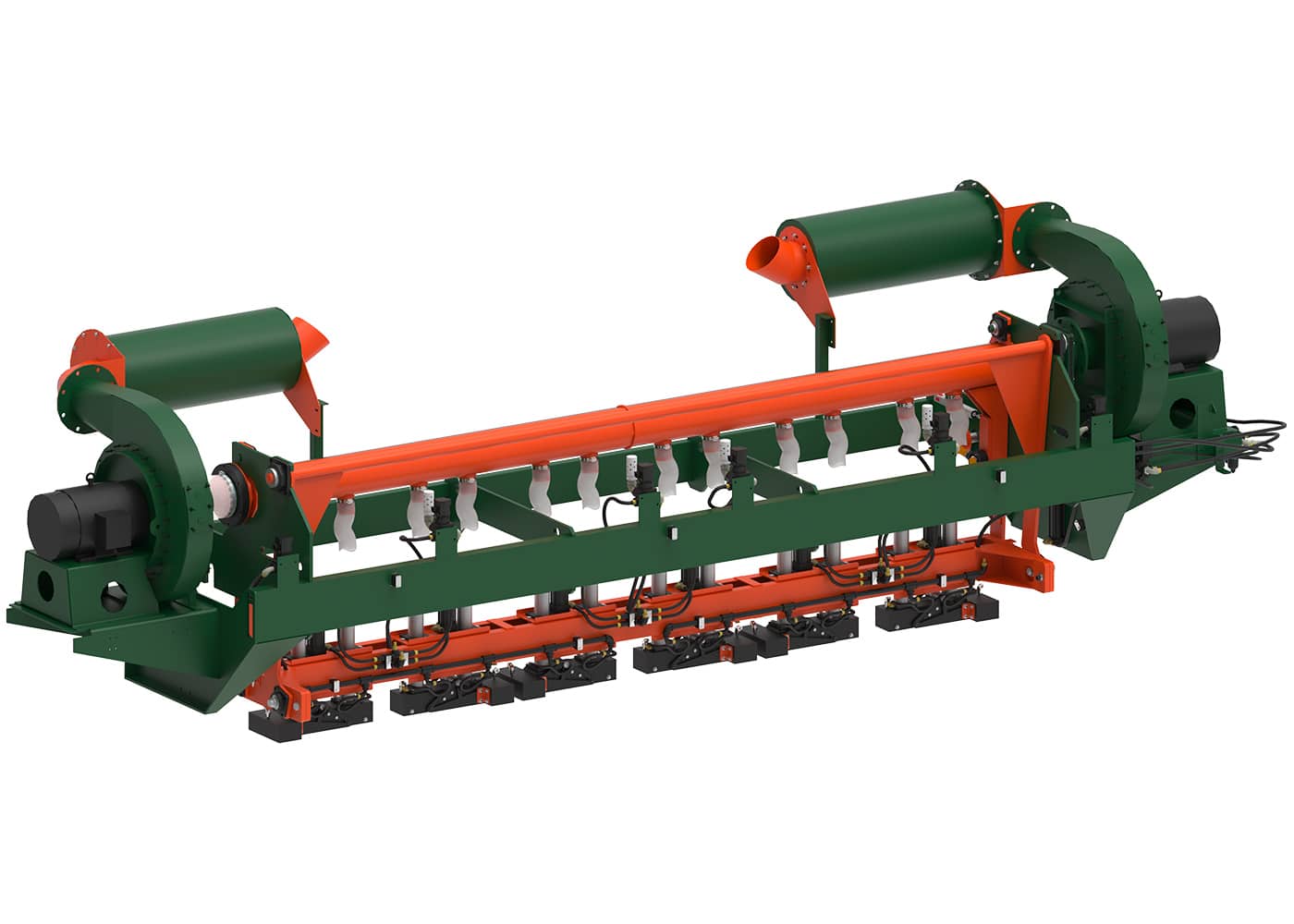

Veneer Dryer Infeeds

Vacuum Feeder

Most Efficient and Highest Producing Vacuum Feeder in the Industry.

The Sweed high-speed Vacuum Feeder streamlines the veneer dryer feeding process by employing a vacuum-driven system for picking up and delivering veneer to the dryer feeder. This system features a vacuum cup beam that operates through a cyclical drive, which mechanically changes direction with each cycle. This drive is powered by an electric motor and a hollow-shaft worm-gear reducer. The unique motion of the beam ensures the smoothest and fastest vacuum feeder currently available in the market.

Whether you choose to utilize the traditional SWEED “bump” feature by itself or decide to incorporate the innovative patented “peel” style vacuum cups, SWEED empowers you to effectively eliminate double feeds and maintain a feeding rate up to 66+ sheets per minute. This capability allows you to maximize the efficiency of your dryer infeed and dryer fill rate, all while being operated by a single operator for your convenience.

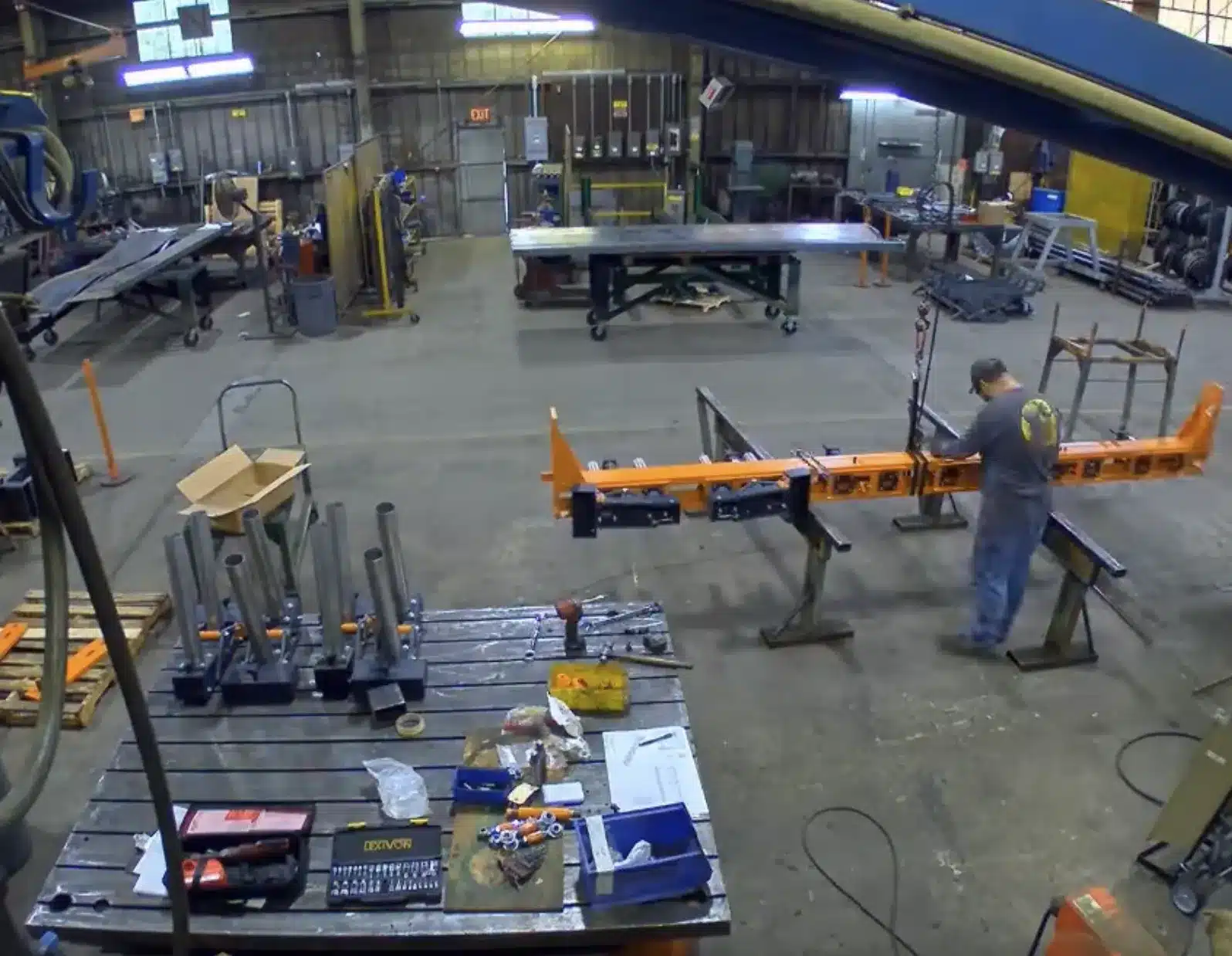

Construction Features

At SWEED, we carry forward the Jeddeloh brothers’ legacy of relentless commitment to construction, craftsmanship, durability, and reliability in our wood products equipment. Designed to perform 24/7, our solutions are renowned for their robust construction, thriving in demanding environments. Our material handling solutions seamlessly enhance productivity and safety, providing the flexibility to optimize your operations, all while maintaining the enduring tradition of exceptional quality that defines SWEED.