Category:

Wood Products

Machine type:

Saws

Core Saw

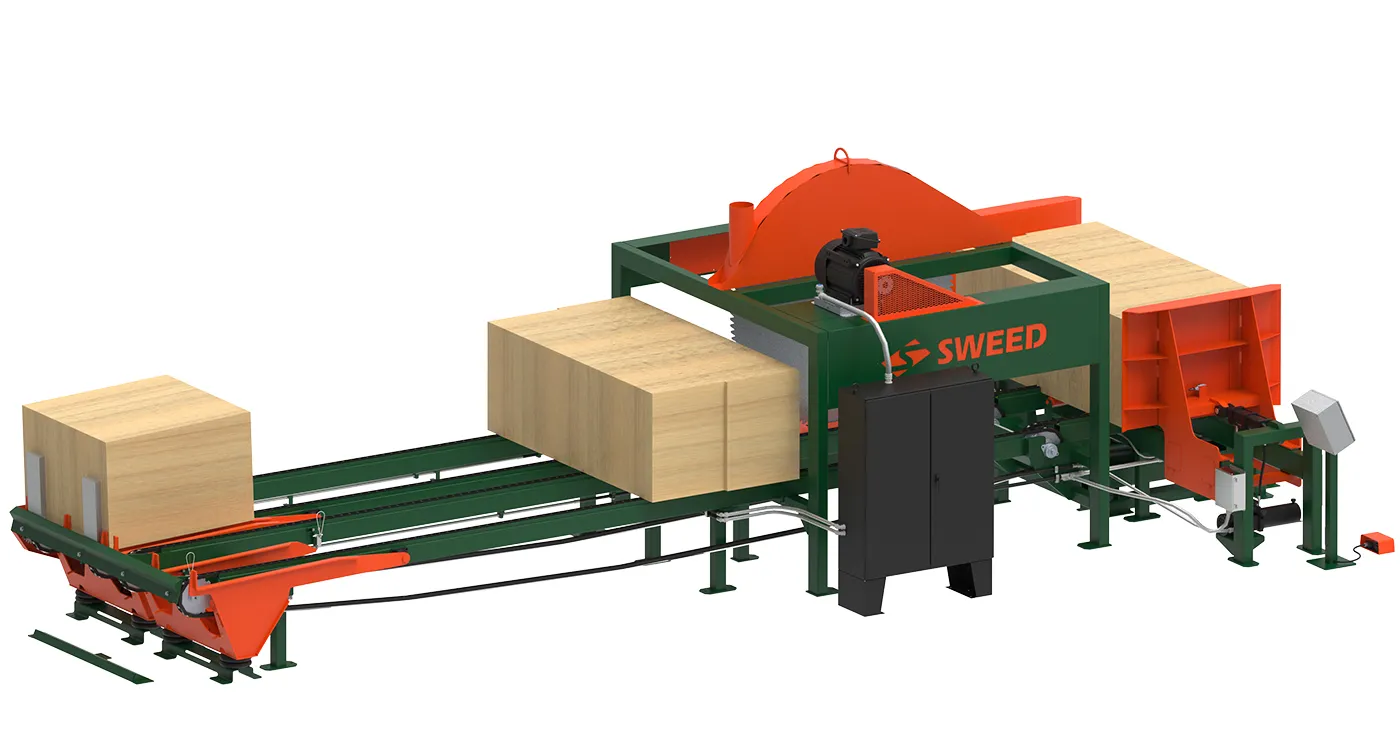

Precision and Versatility: SWEED’S 84-inch Core Saw.

The Sweed Core Saw features an 84″ diameter, 118 tooth blade with replaceable teeth, powered by a 50 HP electric motor. A squaring device ensures precise alignment of materials with the saw blade, and is pressured by a 12″ bore, 14″ stroke air cylinder. The feed chain operates at 22 FPM on a bed of UHMV for reduced wear, with flared chain runways to aid in cut stack separation.

Infeed chains deliver to either a bolt-on outfeed roll case, or powered chain ways, also flared to aid in cut stack separation. Sweed’s Core Saw comes equipped with PLC for basic programming and a single-function center-cut operation. Modifications for offset cuts and/or variable length veneer requiring adjustability are available upon request.

Construction Features

At SWEED, we carry forward the Jeddeloh brothers’ legacy of relentless commitment to construction, craftsmanship, durability, and reliability in our wood products equipment. Designed to perform 24/7, our solutions are renowned for their robust construction, thriving in demanding environments. Our material handling solutions seamlessly enhance productivity and safety, providing the flexibility to optimize your operations, all while maintaining the enduring tradition of exceptional quality that defines SWEED.