Why Chop off-spec Wire and Cable?

Why should wire and cable manufactures chop their off-spec wire and cable?

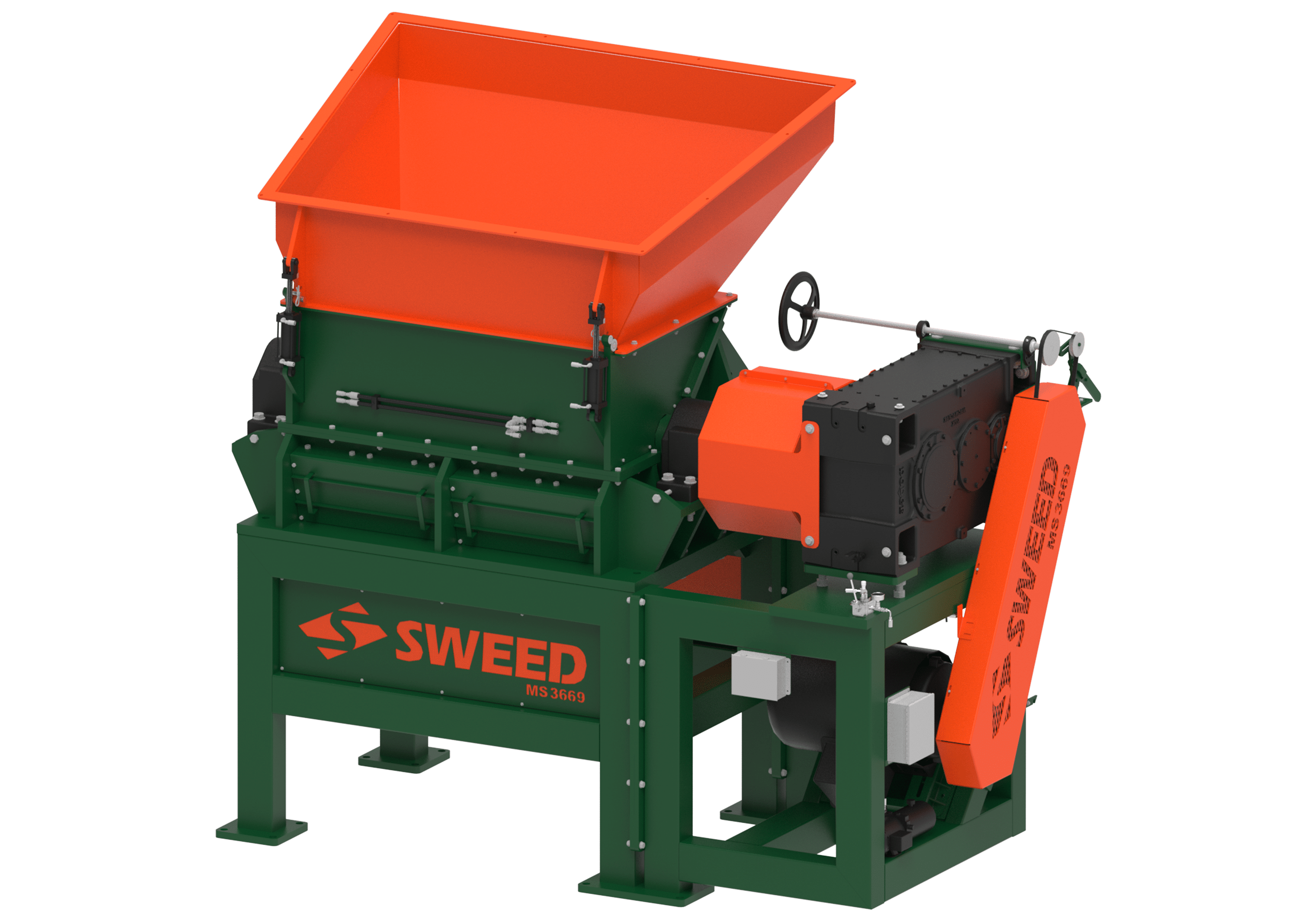

SWEED provides many solutions for wire and cable manufacturers to help them save money on their scrap logistics, increase their scrap value, and recover copper and aluminum from their off-spec material.

Click the GET IN TOUCH button below to reach out to a SWEED representative, or continue scrolling to learn more.

THE LOWDOWN

USE CASES

COMPACTION

Chopping your off-spec wire and cable scrap saves money on the logistics of shipping your spools of off-spec material to and from the scrap dealer.

VALUE

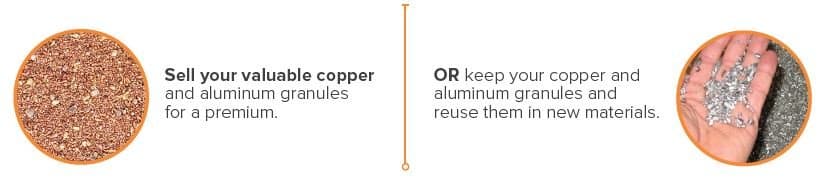

Increase your scrap value by preparing it for recycling.

RECOVERY

Process your off-spec wire and cable in-house.

Whether your goal is to reduce your logistics costs, increase your scrap value, or recover the non-ferrous metals from your off-spec wire and cable, SWEED’s line of recycling equipment can help get the job done.