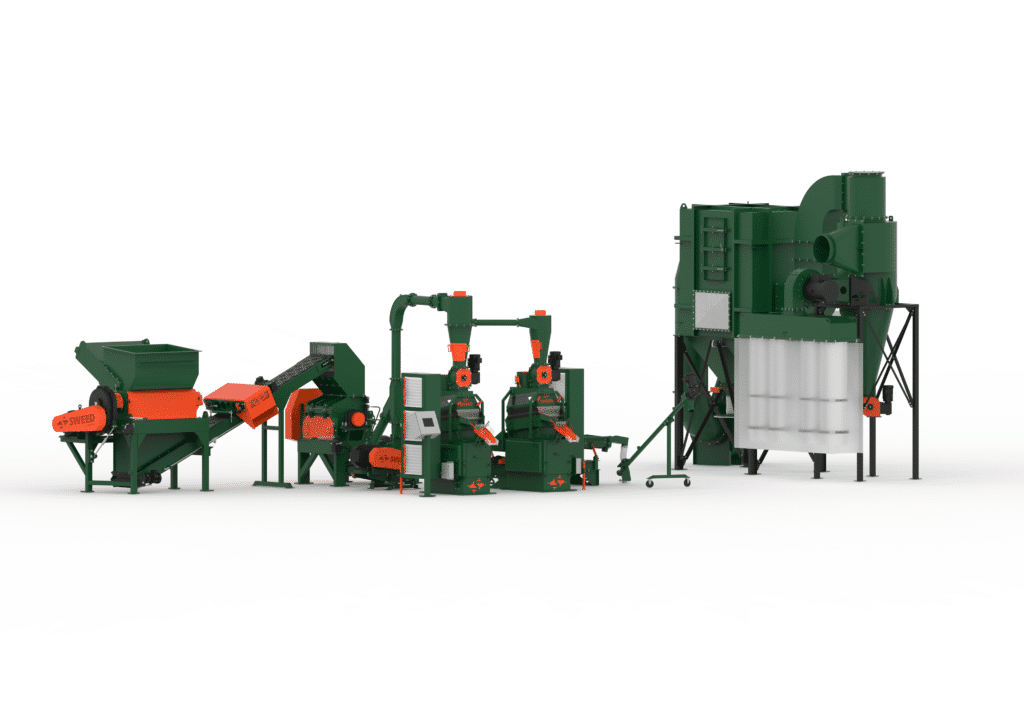

SWEED Introduces Standard Chopping Lines for Nonferrous Recovery: S2000 and S2000+

Gold Hill, OR – SWEED, known for innovative solutions in the scrap metal recycling industry, announces the availability of the S2000 series of wire chopping lines. These systems efficiently handle up to 2,000 pounds per hour and are designed for flexibility, making them suitable for those entering the wire chopping business or considering an upgrade from simpler systems. SWEED maintains parts and components in stock for the S2000 series chopping lines, ensuring prompt builds, and shipping for processors.

The S2000 wire chopping line processes #1 ICW efficiently within a compact footprint, setting high standards for copper recovery, sustainability, and efficiency.

Innovation continues with the introduction of the S2000+, a specialized wire chopping line designed for processing challenging scrap materials. Crafted for low-yield wire and cable, the S2000+ features a turbo mill, ensuring an exceptional copper recovery rate for #2 wire surpassing conventional methods.

Beyond wire challenges, the S2000+ proves its versatility in handling various scrap materials, from wire and cable to ASR, wire harnesses, and more. With dual dedicated air tables, it simultaneously processes copper and aluminum materials, enhancing efficiency and scrap metal processing capabilities.

The S2000 includes:

- PCR1048 prechopper

- Conveyor w/ magnetic ferrous separation

- SG1826 granulator

- 3G air table density separation

- Indoor 3.8k CFM dust collector

- UL 508A control cabinet with Siemens or Allen Bradley PLC & HMI

- Air conveyance material transfer from granulator to air table

The S2000+ features:

- PCR1048 prechopper

- conveyor w/ magnetic ferrous separation

- SG1826 granulator

- TM1815 turbo mill

- (2) 3G air tables in series density separation

- Single deck sifter and auger for plastic output

- Outdoor 8k CFM dust collector

For efficient, sustainable, and versatile copper recovery and scrap metal processing, consider SWEED’s S2000 and S2000+ wire chopping lines. These solutions aim to meet industry standards, providing reliability and performance in every operation.

About SWEED Machinery: SWEED Machinery is a leading provider of material handling solutions, specializing in equipment for the wood products industry, scrap choppers, wire chopping lines, shredders, granulators, shears, and more. With a commitment to innovation and tailored solutions, SWEED Machinery empowers businesses to optimize their material processing and production processes.